Garden Island Dry Dock Optimisation

The Captain Cook Graving Dock (CCGD) at Garden Island (GI) is the largest ship repair and maintenance dock in the Southern Hemisphere and a strategic asset of the Australian Defence Force. It plays a critical role in maintaining the Royal Australian Navy’s fleet, which is vital for national security. Additionally, the facility provides maintenance services for commercial vessels, contributing significantly to Australia’s economy. Due to high demand, the GI facility operates under significant pressure, with limited capacity to dock vessels for maintenance each year. The preparation of the dock between dockings—particularly the positioning and packing of wooden-topped concrete supporting keel blocks—is a labour-intensive and time-consuming task. Minimising this setup time is crucial to maximising the dock’s operational capacity.

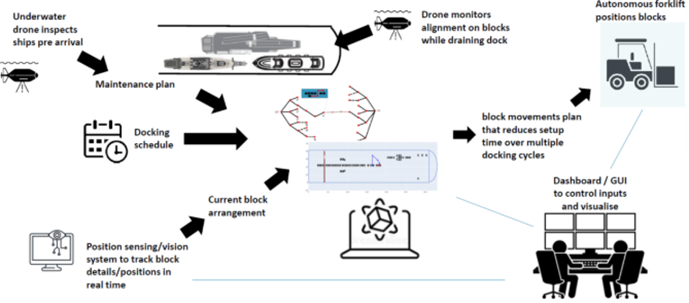

The primary objective of this research project is to develop advanced computational methods that optimise the placement and movement of keel blocks during ship docking operations at the CCGD. By integrating task and motion planning methodologies—techniques used in robotics to plan and execute complex movements and tasks—the project aims to automate the reconfiguration of supporting blocks. This automation will minimise downtime between dockings, thereby enhancing the dock’s operational efficiency. The project seeks to create a system capable of handling the complex constraints and dynamic requirements of the CCGD environment, ultimately reducing the labour intensity and time required for dock preparation.

Research Activities:

Initially, the primary focus was on understanding the challenges and gathering domain knowledge associated with keel block reconfiguration, as well as the ideation and development of a conceptual framework to address these challenges. The researcher spent considerable time at GI to gain an in-depth understanding of the constraints and requirements of the CCGD environment, including the physical layout, operational limitations, and the types of vessels serviced at the dock.

Subsequently, the ARIAM team have designed a methodology rooted in Task and Motion Planning (TAMP). TAMP is a sophisticated approach that integrates high-level task planning with low-level motion planning, making it highly suitable for the complex, multi-constraint problem of keel block reconfiguration. Initial steps were taken to conceptualise how TAMP could be applied to optimise the placement and movement of keel blocks, considering the sequence of docking operations and the specific needs of various vessel types.

An initial ‘simple’ computational tool to demonstrate the ideas of TAMP in the dock has been developed providing valuable insights into the feasibility and potential impact of the proposed approach. A revised methodology is now in development capable of handling more complex scenarios with increased reliability and the ability to find more optimal results.

Expected Impact:

An efficient keel block arrangement can reduce the waiting time for ships to enter the dry dock, which in turn increases the number of vessels that can dock. Currently, keel block (re-)arrangement relies solely on the workers’ intuition and experience which works well when highly experienced workers are available however, when unavailable, this critical preparation may be far from optimal and has a high variance in completion time. Even when highly experienced workers are available, if planning time is short or unplanned schedule changes arise, workers are left with insufficient time to develop optimal re-arrangement plans for the new incoming ships. This problem is potentially further accentuated when the drydock is busy, with a long list of ships already scheduled to dock for service and an unexpected maintenance issue is discovered. A delay due to a sub-optimal keel block arrangement on one ship may cause delays in the service of subsequent ships.

This research project aims to alleviate the above difficulties in keel block (re-)arrangements. These methods will account for the future sequence of incoming ships and be flexible to changes in such a schedule. This will significantly reduce effort involved in planning, eliminate reliance on key people and reduce downtime for the dock increasing time available for ship maintenance.

Associated Researchers

-

Ian Manchester

Director

View Bio -

Hanna Kurniawati

Theme Lead - Planning and Control (ANU Node Lead)

View Bio -

Patrick Haslum

Chief Investigator

View Bio